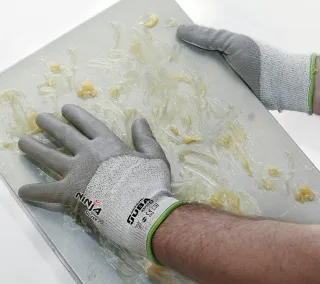

Nitrile Gloves Juba - NT30 NINJA TOTAL

Dyneema®, fiberglass and synthetic yarns with full nitrile coating.

Dyneema® fibre is a robust, ultra-high-molecular-weight polyethylene fibre offering maximum strength with minimum weight. Dyneema® fibre is produced in a patented gel-spinning process in which the fibres are drawn, heated, elongated and cooled. Stretching and spinning leads to molecular alignment, high crystallization and low density. Its extra-long molecular chain structure transfers loads more effectively to the polymer backbone.

Dyneema fibre is used across various sectors of industry where super-strong and safe materials are required, such as the army and the salvage, construction and heavy machinery industries, among others.

Introduced into the personal protective industry, Dyneema fibre provides excellent performance with outstanding abrasion resistance, strengthened cutting protection and countless industrial applications from food to construction.

Dyneema® is 15 times stronger than steel at the same weight and up to 40% stronger than aramids. As well as its extraordinary strength, Dyneema excels in cut and abrasion resistance and has a high resistance to chemicals and UV. Dyneema® fibre is so light that it floats on water and has a very high modulus (resistance against deformation).

Dyneema® Diamond technology delivers unparalleled cut protection, comfort and dexterity. Gloves manufactured with this technology benefit from a single yarn solution that is much thinner than conventional fibres.

It is more comfortable because its fibres radiate heat away from the hands for all-day comfort, without compromising cut protection. The result is gloves that feel like a second skin, yet still deliver a high level of cut protection.

Dyneema has developed an ultra-high-molecular-weight fibre from bio-based feedstock with the same performance as conventional Dyneema fibre, i.e., bio-based Dyneema. Sourcing waste from the timber and pulp industries, bio-based feedstocks are blended with fossil feedstock in the manufacturing process to produce ethylene, the main component used to make Dyneema® fibre.

This latest innovation from Dyneema involves a 90% reduction in the carbon footprint of its manufacture, emitting 29 tonnes less CO2.

Dyneema®, fiberglass and synthetic yarns with full nitrile coating.

Dyneema® fiber blended with fiberglass and elastane, with polyurethane coating on palm or palm and half back.