Actualidad

What kind of work clothes should a welder have?

Welder's work clothes are those specific for welding operations that have to be carried out by professionals in the iron and steel industry.

Welding consists of joining metal parts by means of heat or pressure (sometimes both simultaneously). The most common types of welding are the following:

- Electric welding

- Oxyacetylene welding

In this type of work, the professional is at risk of burns from splashes of incandescent material and from radiation or contact with the work material. This is the main reason for choosing suitable welding work clothing of the highest quality.

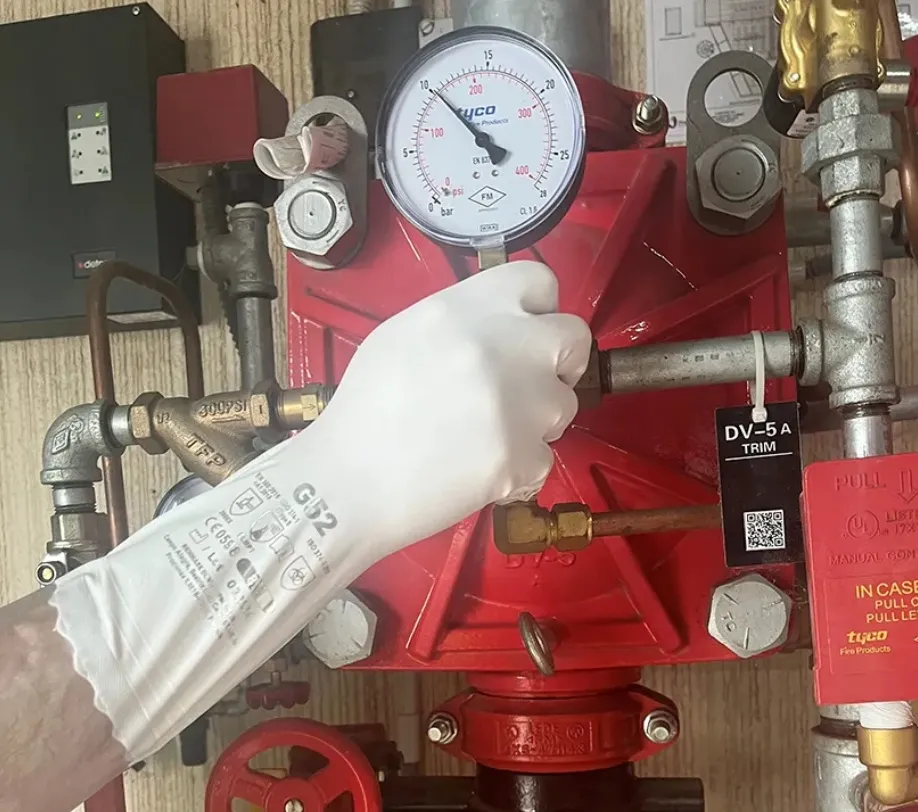

On the other hand, work gloves are essential to ensure hand protection during welding. As this type of activity requires different finishes and levels of precision, it is essential to select the right glove according to the required touch and intensity of the operation, always ensuring maximum safety without compromising functionality.

What are the regulations for welding workwear?

The legal provision for the design and manufacture of welding workwear corresponds to Regulation (EU) 2016/425 on personal protective equipment (PPE).

In addition, the applicable marking regulations may include the following references, depending on the characteristics of the welding work:

- UNE-EN ISO 11611:2015 on protective clothing for welders and related procedures.

- UNE-EN ISO 11612:2015 on protective clothing against heat and flame.

- UNE-EN ISO 14116:2015 on protective clothing against fire.

- UNE-EN 61482-1-2:2008 on the protection of workers against electrical hazards arising from electric arcs.

- UNE-EN 20471:2013 on high-visibility clothing.

The UNE-EN ISO 11611:2015 standard, which is the most specific for welding work, also differentiates between two classifications for protective clothing used during welding and related techniques:

- Class 1: for protection against welding techniques and less dangerous situations, against molten metal splashes and radiant heat.

- Class 2: for protection in more dangerous situations, where the incidence of molten metal splashes and radiant heat represents a greater risk.

What workwear should a welder wear, which is the most suitable?

Juba has extra high quality leather gloves and accessories that offer excellent resistance to contact heat, convective heat, flame and small splashes of molten metal.

In addition, they are designed for durability and protection in hot environments and at risk of abrasion and tearing.

There are two types of welding gloves:

- Type A welder's gloves: these are those with more general characteristics, recommended for welding with metal inert gas (MIG), where the most important thing is that they offer resistance to heat and where dexterity is not so important. They are thick gloves with strong insulation.

- Type B welder's gloves: these include references that stand out for their design in which dexterity is improved for more precise work. However, they perform less well against sparks and heat. They are suitable for TIG welding, where tactile sensitivity is essential.

It should be noted that TIG welding does not generate as much heat as MIG welding. However, heat build-up is still significant and can be transferred, so while they offer dexterity in use, they must also be thick enough to protect against heat. In these cases, goatskin is a very effective material.

Some of Juba's most recommended welding gloves are listed below. Each glove details the characteristics it offers for different types of work:

As for the rest of the welder's workwear, Juba has a wide variety of models to choose from, depending on the area of the body that needs protection.

Split leather sleeves up to the elbow are available in economy versions (451C) or with extra selection leather (251C).

Split leather sleeves up to the shoulder are also available in an economical version (451H) or with an extra selection of leather (251H).

Welding aprons of various types can also be used for welding work. There are various models ranging from the most economical (452A) to options with extra leather selection (252A, 252B, 252AH, 252BH), all of which are of high quality.

For total protection of the welding professional, the 450, 250 and 250C split leather jackets are recommended.

As a complement, you can also count on the Westport multi-pocket waistcoat made of 100% polyester quilted cotton and lined with the same material, which Juba offers in its workwear catalogue in two colours: navy blue (860) and grey (860GY).

The risks of welding do not exclude the lower torso of professionals. For this reason, we recommend the use of trousers such as model 839BL and split leather gaiters such as references 453A, 253A and 253B.