Technical articles

What is the difference between waterproof and waterproof clothing?

In jobs that require exposure to potentially inclement weather, it is important to differentiate between the properties of waterproof and water-resistant clothing, as these terms refer to two different properties.

Waterproof clothing, meaning water-resistant, specifies that it has been designed with materials that will not deteriorate or allow water to seep through in cases of light rain (drizzle) or splashing. Waterproof clothing, on the other hand, ensures that water does not seep in, even in heavy rain or in an environment where there is a high risk of the person feeling the rain on their skin, for example in maritime work.

Therefore, the difference between waterproof and water-resistant clothing is obvious. A garment with the characteristic of being waterproof will eventually leak and the professional will notice that the liquid has penetrated the garment. This does not happen if it is a waterproof reference which, of course, must be properly certified according to EN 343 standard which lists the characteristics that garments must have against the influence of bad weather, wind and cold above -5 ° C. Weather protective clothing is classified according to two criteria: its resistance to water penetration and its level of breathability.

According to EN 20811, the resistance to water penetration of a fabric must be measured in two different conditions: on the fabric and its new seams and on a treated fabric. The fabric can be considered treated if it has been washed or dry cleaned (5 cycles), has been subjected to abrasion, repeated folding and has been subject to the influence of fuels and oils.

To measure the level of breathability of a garment, its resistance to evaporation must be determined. The lower it is, the more breathable the material is considered to be (it lets perspiration escape), while the more breathable the fabric is, the more comfortable it is for the wearer.

Which is better waterproof or water-resistant?

In most of the possible situations where this type of clothing is to be used, the tendency will be to consider a waterproof garment much better than a water-resistant one. However, it is necessary to assess the specific needs of each professional activity.

It is possible that due to the characteristics of a job and the space in which the professional must work, a waterproof garment may not be necessary, so he/she will be able to carry out his/her tasks more comfortably with a waterproof one and the company will avoid investing in the wrong workwear references.

Which material is the most waterproof?

The fabrics that are considered to provide the best performance in preventing water seepage and provide the best breathability are waterproof fabrics such as gabardine, nylon and polyester. Most importantly, in most cases these textile fibres include a special coating, which prevents water from penetrating the fabric. The most common is polyurethane or PVC and a high thread density.

The regulations that waterproof workwear must comply with

The legislation in force, under which waterproof workwear must be certified, is the EN 343 standard for protection against the elements, which establishes the materials and seams of protective clothing against rain, snow, fog and humidity. Specifically, garments are made with particular attention to seams, to guarantee waterproofing of the garment because this is the most vulnerable area. This standard specifies the necessary requirements for clothes to offer maximum protection against rain and bad weather, with respect to the highest standards of waterproofness and breathability.

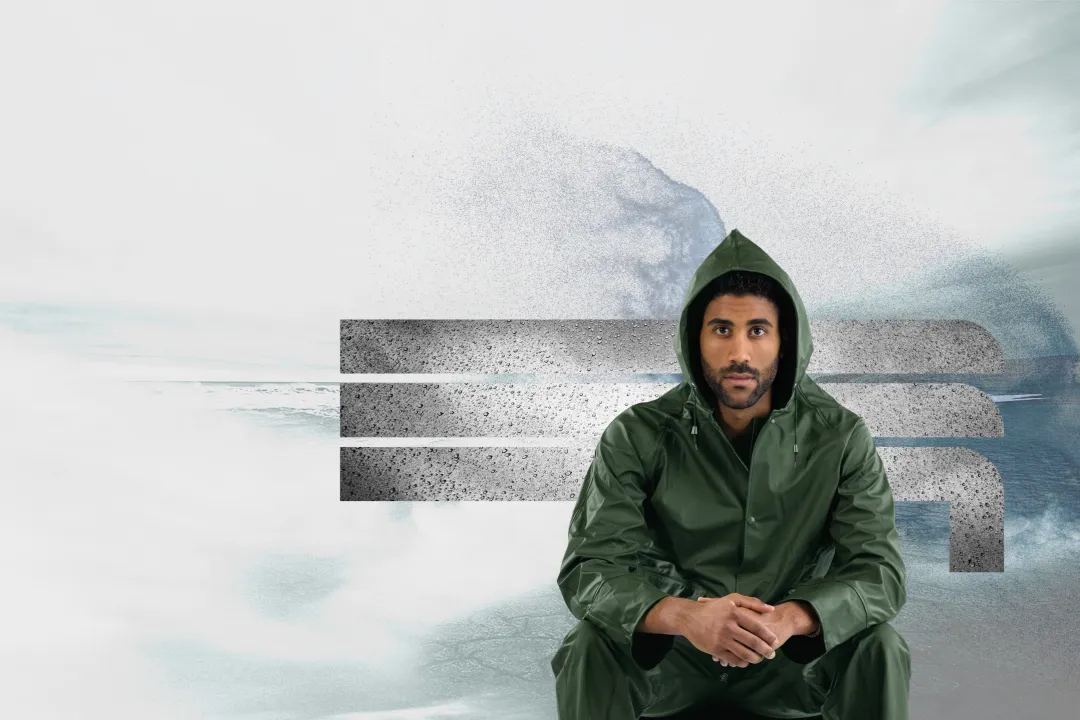

Juba's workwear catalogue features various waterproof references. On the one hand, the full waterproof suit with thermo-welded seams made from 100% polyester material on 0.18 mm thick PVC coating, known as ‘IGUAZÚ’, is available in three colours: blue (802RHAZUL), green (802RHVERDE) and yellow (802RHAMARILLO), and it will resist rain and cold.

This garment is designed with an internal fixed hood with zip fastening, back and underarm ventilation and an elasticated cuff on the inside of the sleeve.

The jacket has a zipped front closure with adjustable drawstring, while the trousers have an elasticated waist and slit pockets.

This reference is an example of waterproof workwear. The waterproof alternative in Juba's catalogue is the ‘DANUBIO’ full waterproof suit, also available in three colours: blue (804RHAZUL), green (804RHVERDE) and yellow (804RHAMARILLO). In this case, the waterproofing of the garment is certified for cold and rain, according to the existing regulations, as can be seen in the product description.

This is a water suit with the following characteristics:

Made from 100% polyurethane on a knitted polyester backing. Polyurethane degrades more slowly than PVC and does not crack, provided it is well maintained.

Very elastic and light, which provides great comfort to the user.

A fixed outer hood compatible with helmets and caps with drawstring adjustment was included in the design of the jacket.

Double zip and placket with button closure.

Elasticated cuff to keep out the cold and rain.

The trousers of this wetsuit, which can also be purchased separately for tasks where upper body protection is not required, have an elasticated waistband.

Waterproof work clothes according to the professional sector

First of all, it is important to think about the requirements of a job depending on the needs of both the professionals and the environment in which the professional activity is carried out.

In general, waterproof workwear is most commonly used in all outdoor jobs where there is a risk of heavy rain or constant water, from construction to agriculture, gardening or even fishing and all types of work related to the sea.

Care for waterproof or water-repellent work clothes

The best care is to follow the care label on each garment. Thereafter, this type of clothing should be kept aired on a day-to-day basis so that it does not become caked. In case of soiling, it is advisable to treat the dirtiest areas, e.g. collar, sleeve cuffs or pockets, before putting the garment in the washing machine.

In any case, cleaning should never be a recurring action, although most Juba wetsuits can be washed at 30 degrees in the washing machine.

Some simple steps to clean a wetsuit:

Conventional detergent, fabric softener or bleach should not be used for washing, but it can be an interesting option to opt for liquid products for delicate clothes or special products for technical and outdoor garments that can be rinsed well. Powdered soap should never be used, as it can clog the membrane.

All zips and velcro should be closed before putting the garment in the washing machine.

Select the delicate programme on your washing machine and the washing temperature, depending on the membrane in question, between 30 and 40 degrees, unless otherwise indicated on the washing label.

Then allow the garment to air dry.

29 October 2024

Read more