News

Juba Workwear: clothes for those who are always on the move

There are people who never stop. They start the day with energy and finish it having given their best. For them, workwear is not just a uniform: it’s a partner that must rise to every challenge.

That’s the idea behind the new Juba Workwear concept, under the motto “Juba is action". A collection designed for those who know that working well also means feeling comfortable, safe, and yes—stylish.

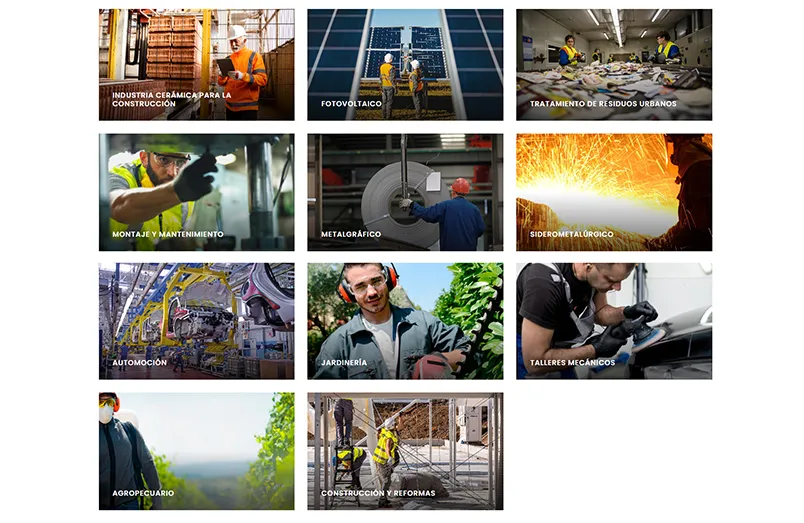

Dressing to overcome any challenge

This new Juba collection goes far beyond the basics. Each garment is created to resist, endure, and move with you throughout the day, without compromising on modern design. From ultra-light technical fabrics that enhance performance, to redesigned iconic pieces that already form part of the brand’s legacy.

The Tech Pro line is a perfect example: lightweight, breathable, and durable clothing made for those who perform at their best and need workwear that won’t let them down.

More than clothing, a philosophy

Behind Juba Workwear lies a different way of understanding professional apparel. The collection is built on four values that go beyond fashion or functionality:

Safety: because protection always comes first.

Quality: materials tough enough for the hardest days.

Sustainability: garments that respect the planet and are made to last.

Innovation: details that make the difference, turning clothing into a true work tool of the future.

Action never stops

With this relaunch, Juba reaffirms its commitment to those who are always on the move. It’s no longer just about making protective gloves, but about offering a complete solution that supports professionals at every step of their journey.

Because workwear can also inspire confidence, bring style, and make a difference. And Juba Workwear is here to prove it: action never stops—and neither do they.

8 October 2025

Read more